Company founded by Al Vel and his son, Ray Velthuysen.

AG invests in CNC milling and turning capabilities, enhancing its abilities to provide a wider array of services and at higher volumes.

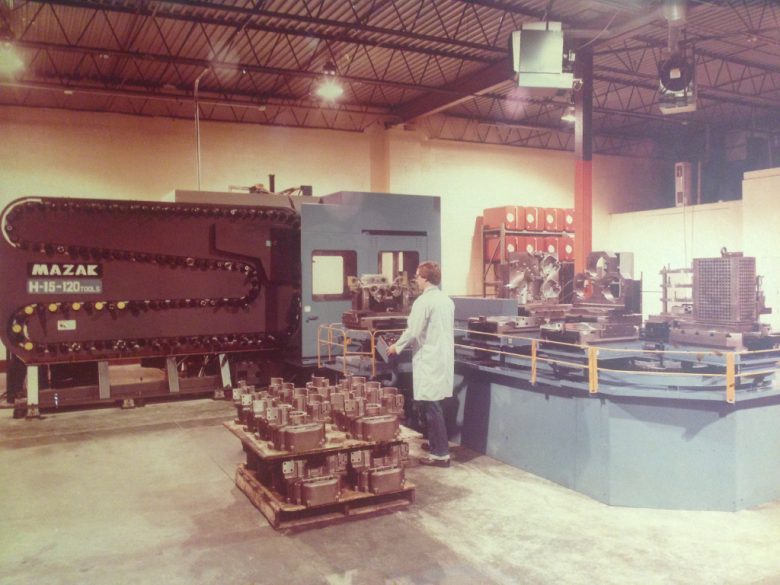

We acquire our first Horizontal Machining Center, improving the quality and capabilities of our in-house machining, our first Coordinate Measuring Machine and begin contract inspection services. We also take over our first production job, an air disc brake caliper which we still run to this day, taking over for the initially chosen and then failing supplier.

Production philosophy begins to evolve around multi-pallet machining centers and three-shift operations. Production includes steering knuckles, gear blanking, auto-slack adjusters, brake cams and prototype machining of heavy axle carrier mountings.

AG provides initial launch volumes for Rockwell truck transmissions, supporting production for several years while they develop internal capacity.

AG continues to support market overflow capabilities for the heavy truck axle business as well as for some lighter automotive components, and continues to improve market response capabilities thru enhanced manufacturing flexibility.

AG becomes a crucial overflow supplier for production carrier mounting machining as market demands eclipse OEM capabilities.

AG supplies over 100,000 carrier mountings, 100,000 steering knuckles, 100,000 clutch covers.

AG takes over M2 carrier machining for Axle Alliance from failing supplier.

AG launches the New Ford Thunderbird Carrier Housing machining for Ford-Sterling Hgts.

AG begins machining of Mack proprietary axle mountings while still supporting traditional programs.

Chosen by Quality Magazine as “Quality Plant of the Year”, Small Plant Division.

Arvin Meritor awards Accurate Gauge the MRAP Carrier program. The Axle will be placed on the BAE-MRAP vehicle; the MRAP vehicles deployed to Iraq to help protect American Armed forces.

Axle Alliance chooses AG to take over M4 carrier machining, making AG sole supplier for M2 and M4 carrier machining.

AG takes over 14X carrier machining for Meritor from yet another failing supplier.

AG returns to Mack mounting machining.

Dana chooses AG, through Neenah Foundry, for consolidation of 80% of Dana commercial carrier machining in 2015. Production expands to three facilities. Overall carrier shipments eclipse 435,000 (60% Growth).

Chosen as Meritor “Drive Axle Supplier of the Year” Also chosen by Rochester (MI) regional Chamber of Commerce for 3 year “Steady Growth” award. Overall carrier shipments eclipse 585,000 (40% Growth).

Celebrating 50 years in business!

IATF Registration